Our offer includes efficient and energy-saving ALUP variable speed compressors, which guarantee variable compressed air production adapted to changing demand. We offer a wide selection of variable speed compressors that allow you to meet the requirements of various processes in terms of the amount of compressed working medium, its pressure and quality.

We offer devices in a basic version with complete equipment enabling immediate operation - including a refrigerant dryer, a pressure tank, various inlet, air and oil filters, and separators with automatic condensate drain. Our devices can be free-standing, mounted on the floor, on a frame or on a pressure vessel. This allows you to select the optimal device tailored to the needs of each plant.

Our range includes variable speed compressors providing compressed air adapted to the requirements of industrial processes. We offer efficient and reliable devices that are easy to use thanks to intuitive controllers. Moreover, ALUP variable speed compressors ensure trouble-free operation and minimal operating costs - both in terms of operating and service costs. We offer solutions with power ranging from 7 to 160 kW and providing a medium with a working pressure of 4 to 13 bar.

The variety of available models allows you to select a device for the needs of various industrial processes. A common feature of the presented ALUP variable speed screw compressors is high energy efficiency resulting from the smooth variability of the production of medium for the needs of production processes. If you are looking for a proven device that will produce cheap compressed air for many years - contact us! We will help you choose a model that will match the parameters of the production processes in your plant.

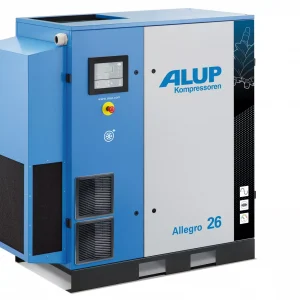

ALUP variable speed ALLEGRO and EVOLUTO compressors are equipped with an air compression system with variable capacity. The motors used in them allow you to reduce electricity consumption by up to 45% compared to compressors with constant capacity. At the same time, the variable speed system extends the life of the machines, ensuring maximum reliability. In variable speed compressors you will find IE3 and IE4 motors with permanent magnets.

For high energy efficiency, ALUP has equipped variable speed compressors with an optional energy recovery system. It allows you to recover up to 75% of the heat emitted during the air compression process, which can be used for other tasks in the plant. Importantly, the energy recovery system is maintenance-free and mechanical. It is also not prone to failure.

An important parameter, especially for smaller plants with limited space, is the noise emitted during compressor operation. The variable speed compressors available in our company are characterized by quiet operation, which allows them to be installed at a workstation. The resulting shortening of the installation is beneficial for the plant - it allows for savings in the construction of the installation and reduces the risk of leaks and pressure drops in the network.

ALUP variable speed compressors ensure high quality compressed air. Options include versions with a refrigerated dryer and a cyclone separator with automatic drain, which eliminates 90% of moisture from the compressed working medium. An additional advantage is a wide selection of air and oil filters.

Most ALUP variable speed compressors are designed to operate in difficult room conditions. They work well at air temperatures up to 46oC. The switchboard of these devices can operate at temperatures of up to 55oC. High humidity and dust in the room are not an obstacle, which is prevented by appropriate filters and air treatment devices.

ALUP variable speed screw compressors use intelligent controllers to optimize compressed air production and increase the efficiency of the devices. Touch screens with graphic communication allow for intuitive machine control. What's more, most models can also be remotely controlled. Moreover, in addition to monitoring the operation of devices, the controllers generate warnings about faults and service activities in accordance with the service schedule. Our offer for larger plants includes controllers supporting a group of compressors.