Variable displacement compressors are becoming increasingly popular in compressed air systems. They are especially useful where variable compressed air demand and energy saving requirements are crucial. How do variable capacity compressors work? And what benefits do they bring to users?

What is the principle of operation of variable speed compressors?

Variable speed compressors are devices whose operating principle is to regulate the rotational speed. As a result, compressors adjust their performance to the current needs of the production process in terms of the amount of compressed air supplied.

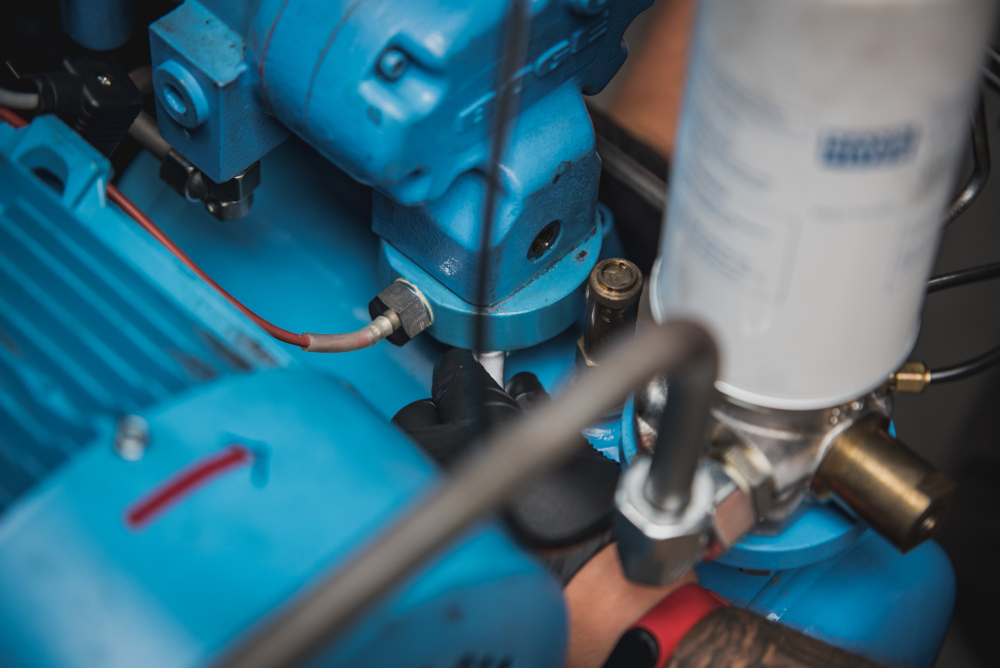

How do variable speed compressors work? Variable speed compressors are screw compressors in which asymmetric rotors allow air to be compressed as a result of changing the volume of the compression chambers located between the rotors. The key to variable performance is engine speed control. Such a compressor regulates the rotational speed of the rotors in the compression element depending on the current demand of the process. In the case of variable speed compressors, advanced control technologies are used to control the rotational speed of the compressor. The inverter technology used allows for smooth speed regulation, which affects the stability of the system. As a result, thanks to the ability to regulate speed, variable speed compressors are more energy efficient in conditions of variable compressed air demand. They can adjust their performance to actual needs, which leads to energy savings compared to compressors operating at constant capacity.

What are the benefits of using variable capacity compressors?

Using variable displacement compressors in compressed air systems offers a number of benefits, especially when compared to traditional fixed displacement compressors. Their basic and most visible advantage is energy saving. One of the most important benefits is the ability of variable speed compressors to adjust operation to the actual compressed air demand of the processes being powered. In case of lower demand, the speed can be lowered, leading to significant energy savings compared to fixed capacity compressors. As a result, the devices are more efficient in systems where the load varies depending on the time of day, week or season.

Flexibility in the supply of the working medium and the resulting reduction in energy consumption are not the only benefits that the machine user gains. Variable speed compressors can run smoothly, eliminating peak energy consumption associated with frequent starts and stops. As a result, by minimizing operation in the start-stop mode, common for constant capacity compressors, they eliminate the problem of higher energy consumption necessary during start-up. This solution also has a positive effect in extending the life of the machine. Smooth regulation of the compressor's rotational speed makes it work in a more stable manner, which translates into less mechanical wear and a longer compressor life.

Let's go back to the lower energy consumption of the variable speed compressor. Adapting the machine's operation to the changing demand for compressed gas significantly improves the energy efficiency of the compressed air system. At the same time, the use of such a design solution in the plant significantly reduces the operating costs generated by the compressed air system. This applies to both expenses related to lower electricity consumption and lower machine wear. It is worth remembering that most (over 70%) of all compressor-related costs (taking into account both purchase and operation, including inspection and service costs) over the life of the machine are electricity expenses. Reducing the electricity consumption of the compressed air system will directly result in lower expenses and an increase in the company's competitiveness on the market.