Compressors are mechanical devices that must be regularly inspected, maintained and serviced. What activities should he carry out? sam user and what professional compressor service? What elements should be reviewed and how often? See what you, as a compressor owner, should do to keep the compressor in perfect condition for many years.

Compressor manufacturers recommend systematic inspections of devices. Inspection of work and parts should take place on a daily, weekly and monthly basis, depending on the scope of the inspection. It is worth remembering to follow the safety rules, which are usually specified by the manufacturer in the user manual.

Daily compressor inspections - what should they include?

The daily inspection of the compressor will be limited to checking the information presented on the controller display. There you will find data on the operating status and parameters of the compressor, including pressure, temperature, rotational speed, etc. Information about detected irregularities in the compressor's operation is also displayed here. It is also worth paying constant attention to the compressor during operation and in case of disturbing sounds coming from the machine, turn it off and perform a more detailed inspection.

What does weekly reviews include?

As part of the weekly inspection of the compressor, the user should check the condition of the filter mat, which is an element of cleaning the atmospheric air taken in by the compressor. Cleaning the mat comes down to shaking it off the largest dirt. It is also worth blowing it with compressed air to remove finer impurities. It should be emphasized that if there is a hard deposit on the mat, the mat will be unusable and will need to be replaced with a new one. Why is cleaning the filter mat important? It protects the internal parts of the compressor against damage caused by large contaminants. At the same time, a contaminated filter mat does not allow for effective cooling of the compressor.

Condensate drains should also be checked weekly. These elements responsible for removing condensate from the system must be kept unobstructed at all times. This eliminates the increased risk of corrosion of the device, pressure vessel and other system components.

What should you check in your compressor once a month?

It is worth checking the oil level in the compressor every month. Please remember that the lubricant in compressors is responsible not only for lubricating the moving parts, but also for cooling and cleaning the contact surfaces. If the oil level is too low, the compressor may overheat and consequently turn off. Therefore, it is necessary to take into account the need to supplement the deficiencies of the lubricant.

Compressor service - usually once a year

Compressor service performed by a specialist company should be performed at least once a year, or after 1-30 thousand km. device operating hours. Detailed instructions on the service system are provided by the manufacturer of a specific device.

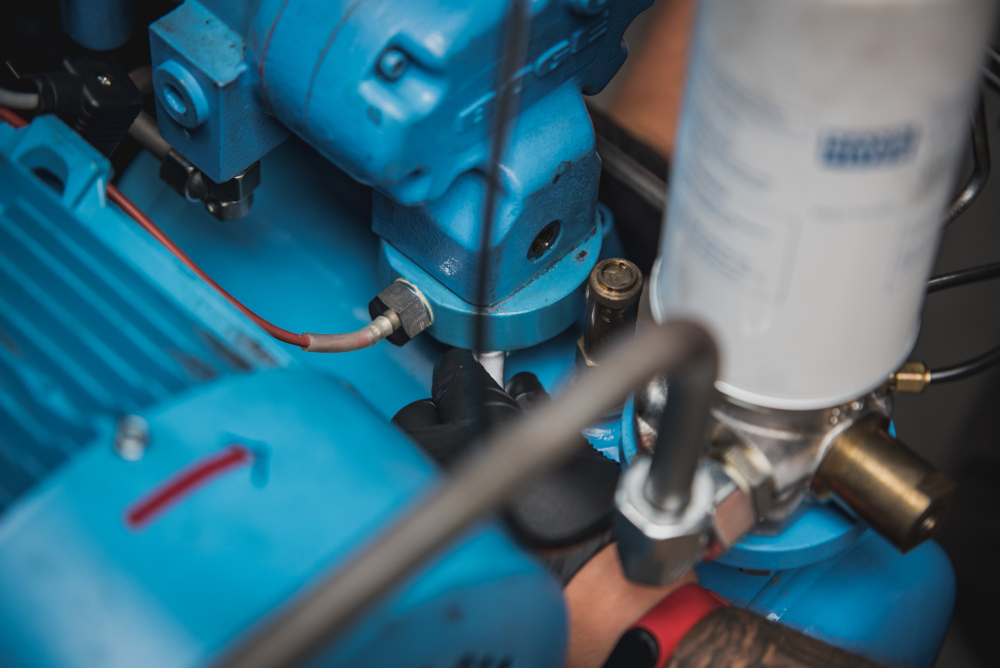

As part of the service, technicians replace air filters, oil filters and oil changes. They check the compressor drive system, including drive belts and clutches, and if these elements are worn, they make necessary adjustments or replacements. During service work on the compressor, it is also necessary to check the operation of the compression system (piston system, screw element), cooling system, electrics and control. It is also important to check the suction and outlet valves as well as safety devices and safety valves. If there is a pressure vessel in the system, it should also be serviced to maintain its integrity and operational safety.

Regular inspections and servicing of the compressor guarantee its long and reliable operation. It is worth emphasizing that a properly maintained compressor will be able to operate efficiently and without failures for more than 100 hours. man-hours. Therefore, it is worth investing in appropriate preventive measures, which will translate into higher compressor efficiency, lower operating costs and reduce the need for faster and large investment outlays.